Benefits of using iPaaS for Supply Chain Optimization

In the current business landscape, companies are exploring novel ways to optimize their internal operations and drive revenue. In this regard, having a highly efficient supply chain ecosystem can prove to be a game-changer for any organization. The COVID-19 pandemic has disrupted the traditional supply chain models and has compelled businesses to leverage digital tools to manage their supply chains effectively.

Recent research by Gartner shows that the pandemic has accelerated the adoption of integrated supply chain solutions and digitization of supply chain management systems. As a result, businesses are inclined towards innovative technologies to upgrade their existing systems or migrate to more advanced ones.

Aonflow iPaaS – Free for First 3 Months!

Build and run up to 1,500 transactions monthly with no cost. No payment info needed!

As supply chain organizations started searching for integrated supply chain management solutions, visibility emerged as a crucial area of focus. In this context, the use of iPaaS solutions that provide shippers with real-time visibility of their end-to-end supply chains has become increasingly popular.

The convergence of external industry pressures and IT demands has created an environment for supply chain optimization through iPaaS. This integration platform as a service provides businesses with streamlined data integration, improved collaboration, greater scalability, enhanced security, and lower costs, ultimately leading to efficient supply chain management.

Let’s first talk about the supply chain industry

Challenges

In a typical supply chain setup, organizations face several challenges such as increased competition, rising material costs, and customer demands. Unfortunately, the absence of a shared goal to increase profits and mitigate risks can make it difficult to navigate these issues.

To improve customer experience and operational efficiency, manufacturers need to collaborate effectively with their partners. Unfortunately, poor communication and information exchange can lead to increased expenses and the loss of valuable processes.

The lack of visibility and reusability, coupled with the complexity of legacy systems, has made it challenging for supply chain industries to address the growing customer demand. A good example of the integration and business-to-business challenges that companies face is depicted in the two images here.

Two of the most common supply chain management challenges that organizations face include:

The Supply Chain Management diagram portrays the intricate integration between data and ERP. However, businesses face several challenges while implementing this system. For instance, they deal with multiple operating systems, incompatible formats such as XML, Legacy EDI –X12, IDOCS, eBXML, TRADACOM, and multiple protocols like HTTP, JMS, FTP, JDBC, SFTP, and more. To add to the complexity, multi-partner onboarding is also required. The diagram showcases the workflow and challenges that arise while implementing supply chain solutions.

Furthermore, businesses face B2B challenges, such as integrating suppliers, manufacturers, warehouses, and stores, coordinating activities across the supply chain, improving performance, increasing transparency, reducing costs and bullwhip effect, and utilizing resources better. Traditional supply chains have many disadvantages and require updating. However, the connectivity between systems, devices, and people impedes the IT organization’s ability to address these demands.

In simpler terms, implementing Supply Chain Management has its own set of challenges, including integrating multiple systems, formats, and protocols. The system requires coordination across the supply chain and improving transparency while reducing costs. Traditional supply chains have many drawbacks and need upgrading, but the lack of connectivity between systems, devices, and people is a hurdle.

Modernization of the supply chain

In today’s fast-paced world, modernizing your supply chain is essential for staying ahead of the competition. One way to achieve this is by adopting an integrated platform as a service (iPaaS) solution. Doing so can improve your relationships with partners and boost your revenue while minimizing risks.

Upgrading your supply chain with iPaaS technology can give you a leg up in the market by streamlining your processes and making your operations more efficient. By integrating all of your systems and applications into a single, easy-to-use platform, you can reduce the risk of errors and delays that can lead to lost revenue and customer dissatisfaction.

In addition, iPaaS can help you build stronger relationships with your partners. By providing real-time access to data and analytics, you can collaborate more effectively and make more informed decisions together. This can help build trust and foster a sense of mutual accountability between partners, leading to stronger, more profitable relationships.

Modernizing your supply chain with iPaaS technology is a smart investment for any business looking to improve its competitive edge and build lasting partnerships with suppliers and customers alike.

Benefits of supply chain integration

Supply chain integration can offer numerous benefits to both organizations and suppliers. However, implementing and supporting an iPaaS supply chain management system can be a challenging task.

The advantages of supply chain integration are many. For organizations, integrating their supply chain can lead to increased efficiency, reduced costs, improved communication, and better customer satisfaction. By streamlining processes and making information more accessible, organizations can make better decisions and respond quickly to changing market conditions.

Suppliers can also benefit from supply chain integration. By having real-time access to data and analytics, suppliers can anticipate demand, manage inventory, and reduce waste. This can lead to more accurate forecasting, better pricing, and improved customer satisfaction.

While the benefits of supply chain integration are clear, implementing an iPaaS system can be complex and time-consuming. It requires a significant investment of resources, including time, money, and expertise. Additionally, supporting an iPaaS system can be challenging, as it requires ongoing maintenance and updates to ensure that it continues to meet the needs of the organization.

Despite these challenges, supply chain integration remains a valuable investment for organizations looking to improve their operations and gain a competitive edge in the marketplace. It’s important to work with experienced providers who can guide you through the process and provide ongoing support to ensure a successful outcome.

What is supply chain integration and what does it entail?

Supply chain integration refers to the process of connecting all of the various elements of a supply chain, from raw materials sourcing to manufacturing, transportation, warehousing, and customer service. It involves coordinating all of the different functions and stakeholders involved in the supply chain to ensure that goods are produced and delivered efficiently and effectively.

At a basic level, supply chain integration entails the sharing of information between different stakeholders in the supply chain. This can involve the use of technology to facilitate communication and data sharing, as well as the development of standardized processes and procedures to ensure that everyone is working together in a consistent and coordinated manner.

In addition to information sharing, supply chain integration may also involve the development of closer relationships between different stakeholders in the supply chain. This can include closer collaboration between suppliers and manufacturers, for example, or between manufacturers and retailers.

How do supply chain integration and automation work?

Supply chain integration and automation work together to create a more efficient, effective, and responsive supply chain. Automation involves the use of technology and software to streamline and optimize various processes within the supply chain, while integration involves connecting all of the different elements of the supply chain to ensure that they are working together in a coordinated and consistent manner.

One way that automation can support supply chain integration is by facilitating the exchange of information between different stakeholders in the supply chain. For example, automation can be used to automatically update inventory levels in real time, allowing suppliers to anticipate demand and adjust their production schedules accordingly. Similarly, automation can be used to track shipments and deliveries, providing visibility and transparency across the entire supply chain.

Another way that automation can support supply chain integration is by reducing the need for manual intervention in various processes. For example, automated picking and packing systems can help to improve the speed and accuracy of order fulfillment, while automated quality control systems can help to ensure that products are manufactured to consistent standards.

In addition to improving efficiency and reducing waste, supply chain integration and automation can also help to reduce the risk of errors and delays within the supply chain. By creating a more streamlined and interconnected supply chain, organizations can respond more quickly to changes in demand or supply, reducing the risk of stockouts or overproduction.

Aonflow is the leading integration platform.

You can kick-start by integrating your first-ever workflow in just a matter of minutes.

The combination of supply chain integration and automation can help organizations to create a more resilient, adaptable, and sustainable supply chain that is better able to meet the needs of customers while maximizing profits for all stakeholders involved. By leveraging technology and best practices, organizations can stay ahead of the competition and position themselves for long-term success in a rapidly changing business landscape.

Implementing supply chain integration using iPaaS

Supply chain integration is a game-changer for all partners involved, as it has the potential to generate substantial profit margins. By reducing waste and increasing efficiency, supply chain integration can help to conserve resources and reduce costs at every stage of the process, from raw materials sourcing to manufacturing, transportation, and customer service.

Implementing a system successfully can offer numerous benefits, including enhanced reusability, increased productivity, improved user experience, and greater business agility. These benefits can help organizations become more efficient, reduce costs, and respond quickly to changing market conditions.

Another benefit of implementing a successful system is the increased collaboration with suppliers and buyers. By sharing information in real time, organizations can work more closely with their partners, identify issues, and resolve them quickly. This can lead to better relationships, improved performance, and greater customer satisfaction.

A successful system implementation can also lead to faster customer onboarding. By automating key processes and reducing paperwork, organizations can onboard customers more quickly, reducing delays and improving satisfaction.

Long-term sustainability is another advantage of successful system implementation. By implementing a scalable and flexible system, organizations can adapt to changing market conditions and continue to deliver value over the long term.

Automation and better connectivity are additional benefits of successful system implementation. By automating routine tasks and improving connectivity between systems, organizations can reduce the risk of errors and delays, leading to more efficient processes and improved performance.

Reduced process loss and increased revenue are also benefits of successful system implementation. By streamlining processes and reducing waste, organizations can improve their bottom line and increase their revenue.

Another key benefit of supply chain integration is that it allows for better coordination between partners. By sharing information in real time, organizations can work more closely together, anticipate demand, and respond quickly to changes in the market. This can help to reduce the risk of overproduction or stockouts, leading to better cost management and improved revenue.

Supply chain integration is that it can help to improve quality control. By implementing standardized processes and procedures, organizations can ensure that products are manufactured to consistent standards, reducing the risk of defects and ensuring customer satisfaction.

Supply chain integration can also help to reduce lead times and improve delivery times. By optimizing transportation and logistics, organizations can ensure that products are delivered to customers more quickly, reducing delays and improving the overall customer experience.

Finally, supply chain integration can help to reduce risk and increase resilience. By having a more transparent and interconnected supply chain, organizations can better manage risks such as supply disruptions, natural disasters, and geopolitical issues, ensuring continuity of operations and protecting against financial losses.

Supply chain integration is a powerful tool for organizations looking to improve their bottom line, reduce waste, and enhance the overall customer experience. By working together and implementing best practices, organizations can reap the rewards of a more efficient, effective, and resilient supply chain.

So how do supply chain integration and automation work in practice?

Supply chain integration and automation can work in practice in several ways, depending on the specific needs and requirements of an organization. Here are a few examples:

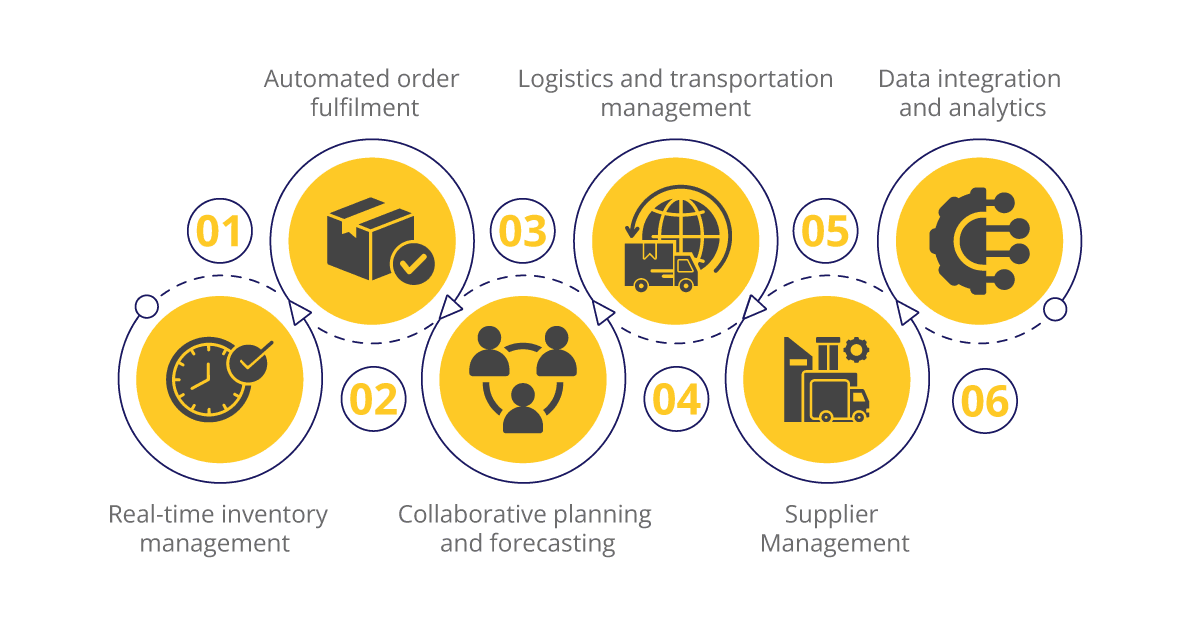

Real-time inventory management: A company may implement an automated inventory management system that integrates with its suppliers and customers to provide real-time updates on inventory levels, demand, and production schedules. This can help to reduce waste and improve efficiency by allowing suppliers to anticipate demand and adjust production accordingly.

Automated order fulfillment: An e-commerce retailer may use automation to streamline their order fulfillment process, from picking and packing to shipping and delivery. This can help to improve speed and accuracy, reduce errors and delays, and provide a better overall customer experience.

Collaborative planning and forecasting: An organization may implement an integrated planning and forecasting system that allows suppliers, manufacturers, and retailers to collaborate on forecasting demand and planning production schedules. This can help to reduce the bullwhip effect and ensure that the right products are produced in the right quantities at the right time.

Logistics and transportation management: iPaaS can be used to integrate with logistics and transportation systems to optimize shipping routes, track shipments in real time, and manage inventory across multiple warehouses and distribution centers. This helps to ensure that products are delivered on time and in the most cost-effective way possible.

Supplier management: iPaaS can also be used to manage supplier relationships and streamline the procurement process. For example, it can be used to integrate with supplier catalogs, automate purchase orders and invoices, and track supplier performance metrics such as lead times, quality, and pricing.

Data integration and analytics: iPaaS can be used to integrate data from multiple sources (such as ERPs, CRMs, and supply chain management systems) and provide real-time analytics and reporting on key supply-chain metrics such as inventory levels, order fulfillment rates, and supplier performance. This helps supply chain managers make better-informed decisions and respond quickly to changing market conditions.

Overall, the specific ways in which supply chain integration and automation are implemented will depend on a variety of factors, including the industry, the size and complexity of the organization, and the specific goals and objectives of the supply chain management team. However, by leveraging technology and best practices, organizations can create a more efficient, effective, and responsive supply chain that is better able to meet the needs of customers while maximizing profits for all stakeholders involved.

Final thoughts

Supply chain integration and automation are essential components of modern supply chain management. By integrating various systems and processes, supply chain partners can work more efficiently and collaboratively, resulting in reduced costs, improved customer service, and increased revenue. iPaaS solutions provide a cloud-based platform for automating workflows, sharing data, and collaborating more effectively. They can be used for a wide range of supply chain management tasks, from order processing and fulfillment to data integration and analytics. Overall, supply chain integration and automation can create a more efficient and profitable supply chain, leading to better business outcomes for all partners involved. Organizations that adopt these practices will be better positioned to compete and succeed in today’s fast-paced and ever-changing business environment.

Aonflow iPaaS – Free for First 3 Months!

Build and run up to 1,500 transactions monthly with no cost. No payment info needed!